The project is divided into two parts: €2.12m for the latest-generation filtration equipment and €1.6m for infrastructure. The aim is to bring the facility into service in spring 2026, with completion of the construction work scheduled for next February.

Strategic step

This modernisation is part of the brewery’s drive to guarantee impeccable clarity. Filtration is a strategic stage in the beer-making process, for both qualitative and industrial reasons. By eliminating suspended particles from fermentation, breweries guarantee microbiological stability and a product that meets market expectations.

This process not only improves visual clarity, but also “produces a beer that is more stable over time,” said production director Maurice Treinen on the sidelines of the groundbreaking ceremony at Bascharage on Thursday 24 April.

Lower water consumption

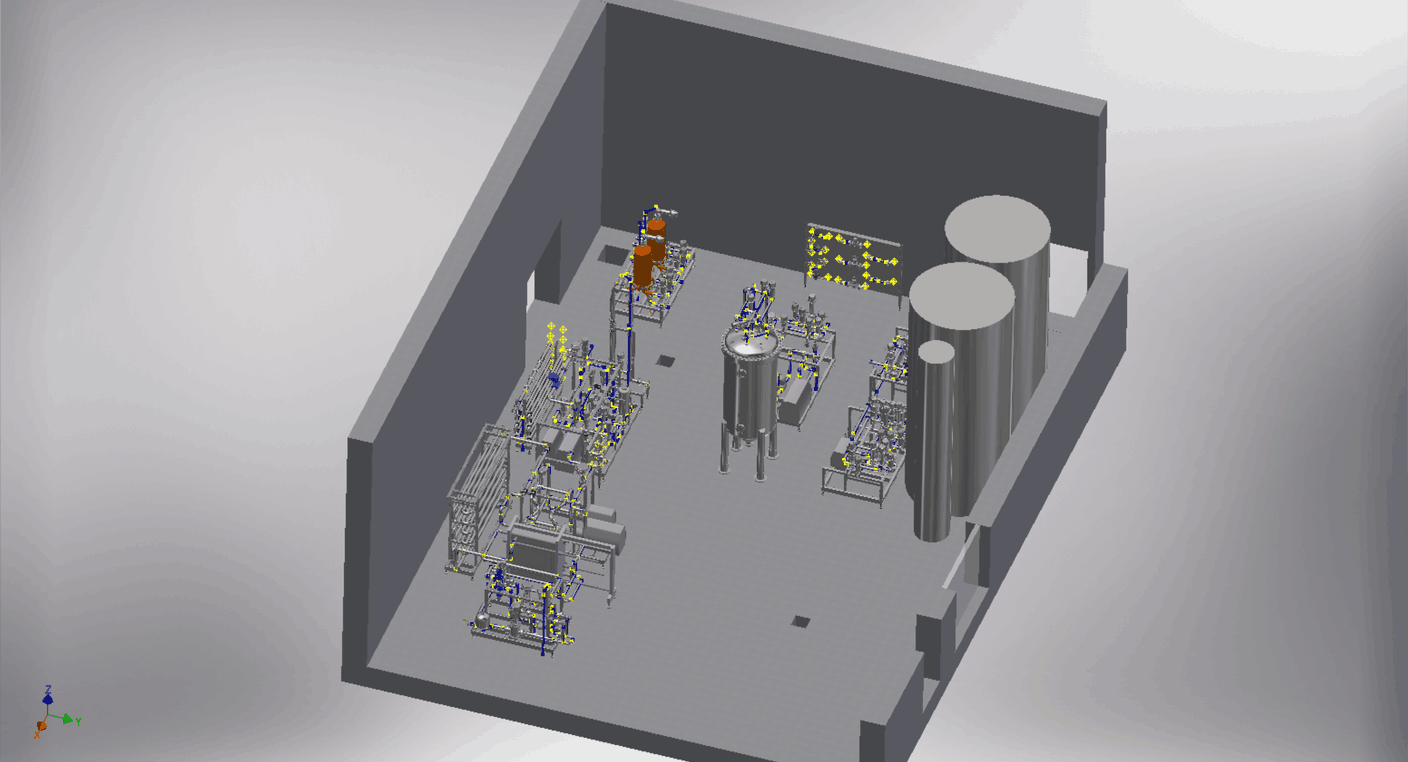

But the innovation goes beyond performance: the new facility promises to reduce the water consumption required for its operation. The result: energy savings and a smaller carbon footprint. “Up until now, we needed 2.5 litres of water to produce one litre of beer. With this complete adaptation of the filtration system, it will be two litres of water for one litre of beer,” continues Treinen, who also stresses the time and performance savings that the new system will generate. The new system will be deployed at the same level as the rest of the production line, whereas the current filtration system is located underground.

“What’s more, everything will be automated. I’ll almost be able to control everything from home,” laughs the manager, who admits to “a bit of stage fright, like at the start of every project.” “It’s quite a heavy investment for the Brasserie nationale,” he adds.

Optimisation

“The Brasserie nationale is making a lot of effort to optimise its production line,” notes Bascharage mayor (CSV), who was present on Thursday. He also emphasised the positive impact on the financial costs of the Pétange wastewater treatment plant. “Things go together. What is undertaken on one side has an effect on the other. Thanks to these investments, the charges were recalculated at the beginning of the year,” he is pleased to say.

No pause in production

There is no question of stopping the machines: production will continue during the construction work. Only the visitor route will be temporarily affected. Guided tours, tastings and brewing classes will continue to be open to the public.

For the rest, rest assured: the Bofferding and Battin beers produced at Bascharage will still have the same flavour! “Our job is to always obtain the same quality,” smiles Treinen.

This article was originally published in .